More Issues

- August 2023

- September 2021

- August 2021

- July 2021

- June 2021

- May 2021

- April 2021

- March 2021

- February 2021

- January 2021

- December 2020

- November 2020

- October 2020

- September 2020

- August 2020

- July 2020

- May 2020

- April 2020

- March 2020

- February 2020

- January 2020

- December 2019

- November 2019

- October 2019

- September 2019

- August 2019

- July 2019

- June 2019

- May 2019

- April 2019

- March 2019

- February 2019

- January 2019

- December 2018

- November 2018

- October 2018

- September 2018

- August 2018

- July 2018

- June 2018

- May 2018

- April 2018

- March 2018

- February 2018

- January 2018

Seven Years

Web ExclusiveI purchased my first car at the age of 14 – a 1955 Chevrolet Tri-Five. The year was 1979; I was introduced to restoration work with this car and worked on it for three to four years in high school.

As my ’55 aged, I lost interest in restoration projects. I had not been active with showing the car for quite some time, and I really wasn’t motivated to get back into the car show circuit (or even the hobby).

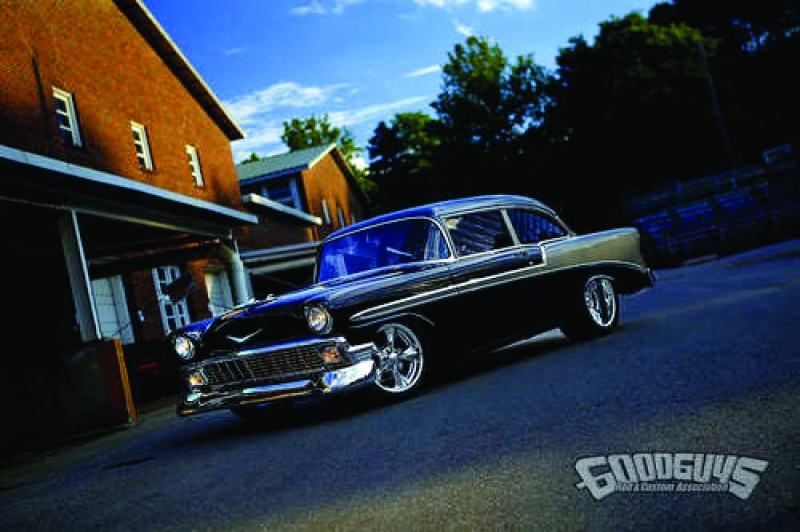

In 2011, I saw a 1956 Bel Air for sale along the road. I always loved the ’56; it was my favorite of the Tri-Fives. I felt a sense of excitement and maybe a little challenged. I purchased the car the following Monday and the journey began. I really did not believe I had the experience or skills to restore a car myself, but there was something motivating me to try a build. I began tearing down the car with my boys and dug into research. My personality type led me to set some high goals. A resto-mod was the goal and I would attempt to build a top-shelf car. I was not sure of my ability; I only had three years of part-time work in the body shop when I was in high school. I never got too deep into the finer skill sets of bodywork and did not even know how to weld. I visited with some of the best builders at various shows, including Goodguys, to get a better insight on building the car.

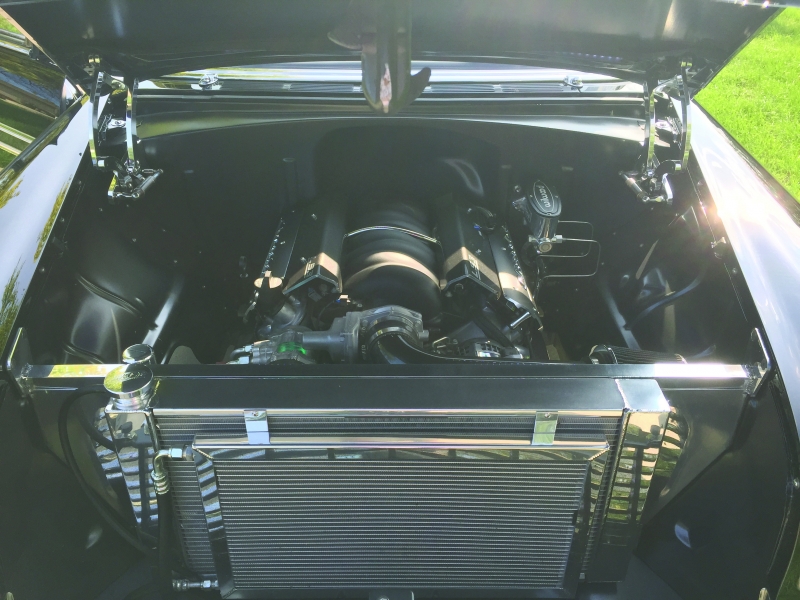

As I got deeper into the project, I discovered I got more than I bargained for. The car had some serious rust and although much of it could have been repaired with patch panels, my attention to detail led me to take more extensive steps to do the repairs. The car has a lot of sheet metal that has been replaced including the complete floor, rockers, inner fender wells, tail pan, lower tail lights, entire tail light openings built around the reproduction tail lights, quarter panels, lower fenders front and a headlight cap. The firewall was smoothed and under the hood was cleaned including panels to hide the wiring and control systems for the engine and transmission. Big tires were a must and I ended up doing a 3" mini tub to make room for the 14” wide tires and 20" rims. I began my welding in the inner rear fender wells and acquired some experience working with the Mig. I worked out from there and ended up doing the quarters last and butt-welded all panels.

At this point, the car was ready for smoothing. The panels were replaced and the car was rust-free, and I had the car media blasted and put in epoxy. I was ready for body filler. I had done some bodywork in the inner fenders and the floors, so I was learning the process while reflecting on what I learned in high school. With that, I was not totally confident in my abilities to produce a straight body. Who could I get to teach me how to do great bodywork? I looked back to my high school years and to the guy who helped me restore my ’55; Randy Harms was the guy. He agreed to helping, but with the understanding that we would do this on his time after his work, so it would be limited to two to three hours per night. Randy must have had a soft spot for me. He was the guy I worked under for three summers in the body shop during high school. He had a reputation in our area as being the best and I believe he is. I spent many hours with him and he shared many of his trade secrets, even metal shaping. He is very patient, meticulous and spent a lot of time getting the panels straight before slapping on the mud.

I got the car all the way to the first prime in about three years. After that, I felt that God was challenging me to set the car aside for some time. It was consuming me. I ended up not touching it for almost one year.

During the winter of 2015, I started blocking the car and the excitement began to build. I contacted a few guys I went to church with – Kevin and Kyle Hoffman – to spray the car. They were young and I barely knew them, but I had heard they did good work. They had a shop and paint booth at their farm and they were willing to let me continue through the build and be a part of the prep process in painting the car.

The car was painted in the spring of 2016 while enduring a serious struggle with fish eyes on the first spray. Somehow – through the power of prayer – we escaped the madness without using fish eye eliminator. We did not finish spraying the car that night. We stopped and pondered what to do. My brother showed up at 11:00 pm and that's what led to four men standing in a paint booth arm in arm asking God for a miracle. God had put me in this situation for a reason and He had put me with the right guys. I am not sure why I had to go through this, especially after all the right steps were taken to prep for paint, but God works in mysterious ways. I think of the restoration of a car similar to the restoration process that God does in our lives. Sometimes the process is difficult and we give up hope, but He faithfully walks with us through it and He always brings good through it. The next morning, we took a serious step of faith and sprayed the car without using fish eye eliminator, and the result was a perfect spray with no fish eyes. Somehow, we ended up with the paint job I had set my goals to achieving. After many hours of blocking and buffing, the true beauty of the journey started to reveal itself.

During the fall of 2016, we started to put the car back together and had hopes to at least take it for a drive before the snow fell in Iowa. Todd Beelner, owner of Stainless Rehab, did the trim. He kept tabs on me and where I was at with the build. When I was close to needing it, he dug in and had it ready. Todd is a great guy with a great work ethic and passion for what he does. He loves the car industry period. The quality of his work is unbelievable and it's worth it rather than replacing it with reproduction trim.

I did not desire to wire the car as this is not one of my strong skill sets, so Todd introduced me to Brent at Dakota Muscle Cars in Sioux City. Brent and his crew got that done for me and they finished a few other mechanical finishes. In November, the car was running. Todd also connected me with Darren Carlson, owner of Boonies Upholstery, Inc., who did the custom upholstery.

It’s amazing to see a car come to life after such a long journey. Almost all my hours spent restoring the car were spent as late nights after work and weekends. That's probably why it took seven years!

I am thankful for the gifts and skills that I have been blessed with to be able to enjoy and experience building a car. It takes a special personality and character to restore a car and I really enjoy the process. Taking something old and making it new again. Respecting what it is and maintaining its integrity but finding ways to improve it.

There are many people that God put in my path over the years and throughout the process to complete this project. I want to thank my wife and children who have been very patient and have missed much time spent with me as well as my parents who brought me up right and taught me many characteristics including work ethic. I also wish to give credit to Rich Morgan, the co-owner of the body shop I worked at, and a mentor to me as I was growing up. I also want to give credit and thanks to Dave Vanmaanen, the owner of Ultimate Auto Body & Glass, for assisting and allowing me to use his paint booth to prime and epoxy my car. He also helped and guided me through many of the steps during the build. Kip Maggert, a local machinist and master at everything, was a huge part of encouraging me and helping me through some tough spots. Kip was a huge inspiration for me with just a few choice words of encouragement. I also want to thank my wife Jackie, daughter Cori, and sons Joe and Jacob for assisting me at times even when they didn't feel like it. I am sure that the process meant more to them than I know right now. They seem to pick up a lot even when you do not think they are paying attention. Who knows, maybe someday they will catch the bug and get into cars. I hope so, we need more young people in this hobby. Keep an eye out for me; I would love to share my story with anyone who desires to listen. So many have helped me and it's rewarding to share and help others.

Heartland Nationals was an awesome weekend! I was honored to receive multiple awards including a Classic Chevy pick, Builder’s Choice and Custom Rod of the Year finalist. I want to thank the Goodguys staff for this unbelievable experience. They do an outstanding job with this show and with the entire Goodguys organization. First-class, professional, organized and very friendly/helpful staff. Everyone I came in contact with was great. I look forward to seeing you all again as I hope to show my car again.